Wolftank Austria responds to the changing gas station industry. The sector is facing times of new alternative fuels, aging assets, and aggressive fuel corrosive. This requires innovative solutions to preserve the asset values.

Fortunately, the company focus includes providing solutions to rehabilitate underground storage tanks, pipes, and sumps effectively. Recent approaches allow making such technologies accessible in any country without interrupting the stations’ operation while making a sustainable investment.

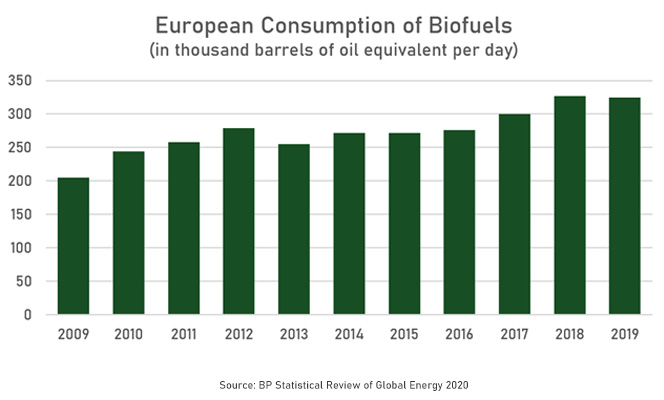

Over the last decades, fuels for mobility did not significantly change and consisted more or less in diesel and gasoline. Recent tendencies led to two new main challenges:

- New energy sources, such as electric energy, liquid natural gas (LNG) and hydrogen

- Bio-additives or biofuels

Both are resources which existing storage tanks need to be prepared for, in order that gas stations stay competitive. The increasing demand for alternative fuels is forcing the industry to adapt or rehabilitate the current underground storage tanks. But many of them are continuing to age. Underground storage tank upgrades with Wolftank Austria technologies allow preserving the assets long-term value while being suitable for alternative fuels.

Rehabilitate instead of rebuild in times of decreasing fuel consumption

The increasing demand of alternative fuels and improving engine technologies lead to an overall decrease in diesel and gasoline consumption. Storage space, however, is necessary also for alternative fuels. Therefore, the demand to preserve the tanks, sumps, and pipes against aging and corrosion keeps unchanged.

In the past, one of the main reasons for a tank substitution was the necessity to increase the storage capacity of gas stations. Nowadays, due to the changing market, increasing the storage capacity is no longer in focus. Slowly but surely, retail networks of every scale require to amplify their traditional fuel sale business to the demand for alternative fuels. LNG or hydrogen, for instance, are demanding its space.

Furthermore, legal regulations for biofuel additions such as methanol and ethanol require high performance lining systems. These must be able to sustain aggressive storage liquids and provide long-term protection.

Wolftank Austria’s product portfolio includes various lining systems suitable for those new requirements. These technologies allow to preserve the existing assets while keeping them profitable over time. The constant effort in research, development and process-optimization, make Wolftank Austria technologies accessible for big retail nets. But also for small-scale networks with a significantly lower budget. With the challenge in mind to make biofuel or alternative energy storage accessible to even smaller retail nets, Wolftank Austria plays a significant role in the global tank rehabilitation and retrofitting of fossil and alternative fuel storage.

Underground storage tanks ready for long term sales

Modern alternative fuels behave more corrosive to steel and fibreglass tanks than traditional fuels. Tank and sump lining technologies, as well as a simple local hole repair executed in time, prevent heavy corrosion and preserve tanks against future corrosive damage.

However, storing alternative fuels and avoiding small investments, such as repairing a local crack with the Wolftank Austria Hole Repair Kit or rehabilitating storage tanks with the DOPA® technology, can lead to spills or in worst case even to a complete shutdown of the business operation. Within shortest time, the damage of a gas stations’ business can drastically increase from a few liters less sold to no sales at all. Undoubtedly affecting the financial turnover, but also the whole surrounding environment and lead into even higher costs and potential legal consequences.

Wolftank Austria possibilities

The widespread availability of such high-performance technologies is of big advantage for the whole gas station industry. Moreover, also playing an important role in maintaining our planet in a natural healthy state, avoiding every type of soil contamination in the underground storage business segment in the best possible way.

In case a soil contamination already occurred or is even just suspected, the global and highly specialized network of the Wolftank Group Group, which Wolftank Austria is part of, possess market-leading possibilities and technologies to analyse and completely restore the healthy state of the surrounding area. Afterwards, Wolftank Austria linings, coatings or sump sealings will make sure such soil contamination is not happening again. For instance, linings, such as Epoflex® 6N or Epoflex®3 are suitable for a broad variety of aggressive storage liquids. Efoflex® 6N even for pure ethanol, while Epoflex® 3 is best-performing for methanol storage (more information about methanol storage, here).

In summary, the gas station market is undoubtedly changing. But Wolftank Austria and its wide portfolio is completely ready for it!