High performance industrial coatings

Industrial coatings

We offer our expertise and innovative solutions for the protection and maintenance of tanks and pipelines.

Our broad portfolio of industrial coating technologies is the result of years of research, innovation and development. We have longstanding experience in petrochemical applications for extraordinarily challenging conditions, such as high pressures and extremely corrosive environments.

Thanks to the constant in-house developments combined with the practical know-how we have acquired over the years, we provide excellent technologies for the lining and renovation of liquid storage facilities. Whether high chemical resistance, food-grade requirements, severe weather conditions or single-to-double-wall refurbishments, our priority is to ensure the safe storage and transport of liquids, with sophisticated products that extend the lifetime of both storage tanks and pipelines.

We promote solvent-free and non-flammable resins to minimize the environmental and HSE impact for all operations. Moreover, our no-man entry solutions are the state of the art in the industry.

We support our customers all around the world by protecting their assets with technologies developed and certified according to national and international standards. The main industries in which we operate are:

Durable

Solvent-free

Non-flammable

TERMINALS & STORAGE

Our products withstand continuous contact with crude oil, petroleum products and fuels as structural and semi-structural coatings. We also protect and condition tanks, vessels and piping for contact with aggressive modern biofuels such as ethanol, methanol and biodiesel.

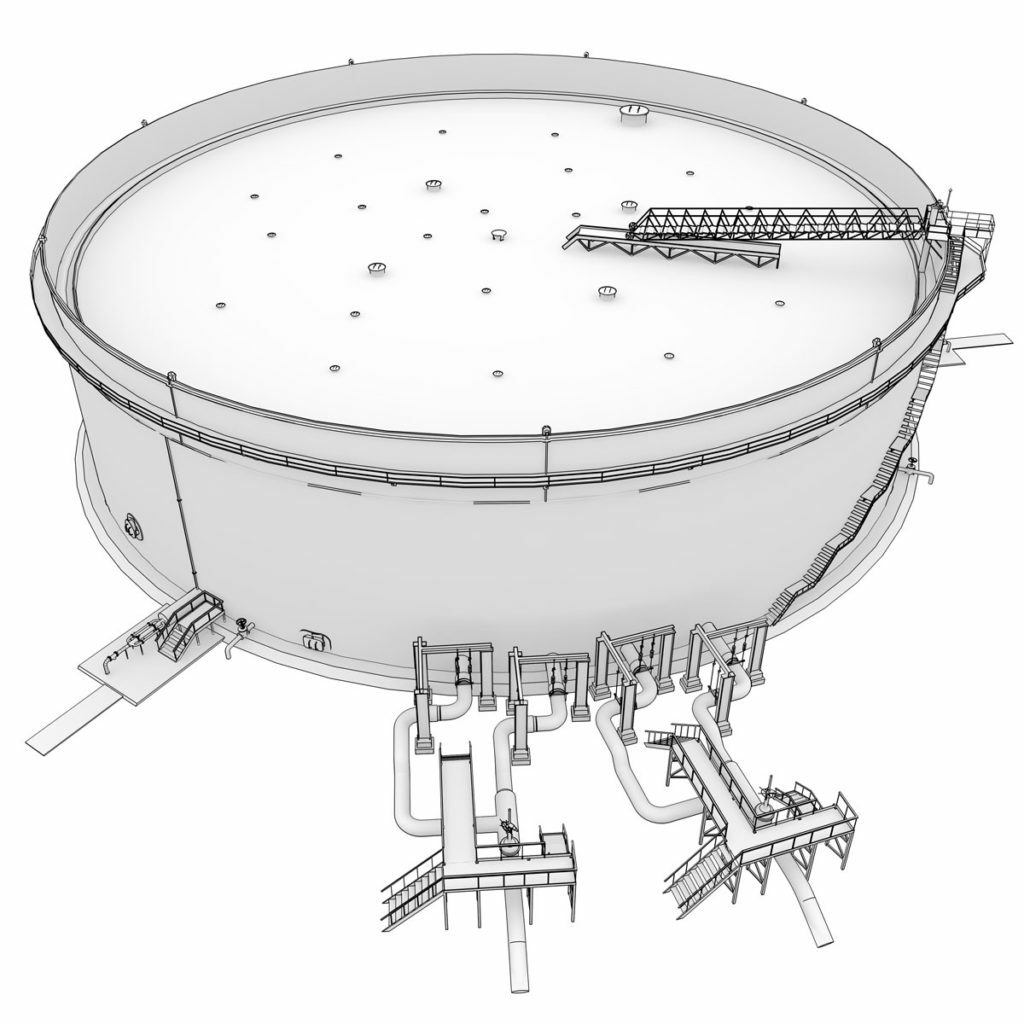

Wolftank Austria puts its knowledge at the service of the market and provides structural linings and corrosion protection for storage tanks on demand. Please check our example of solutions for a bulk storage tank:

- Conductive and non-conductive floor corrosion protections

- Mechanical reinforcement of steel floor with high-performance laminates

- Outside surface sealing for secondary containments

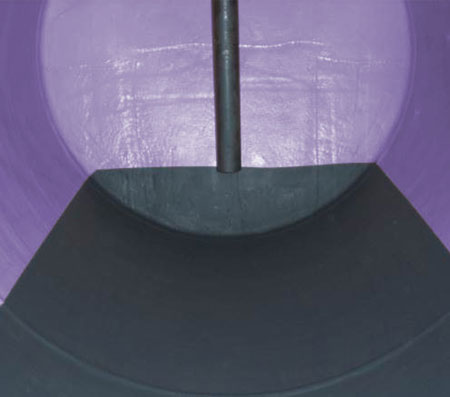

- Internal double floor linings with DOPA® vacuum monitoring

- Outside corrosion protection for C4-C5 environments

- Reinforcement of ring walls

- 24/7 tank monitoring under vacuum ensuring the asset integrity

- Floors retrofitted to double floors

- Maintenance operations, such as tank cleaning, sludge removal and spill management

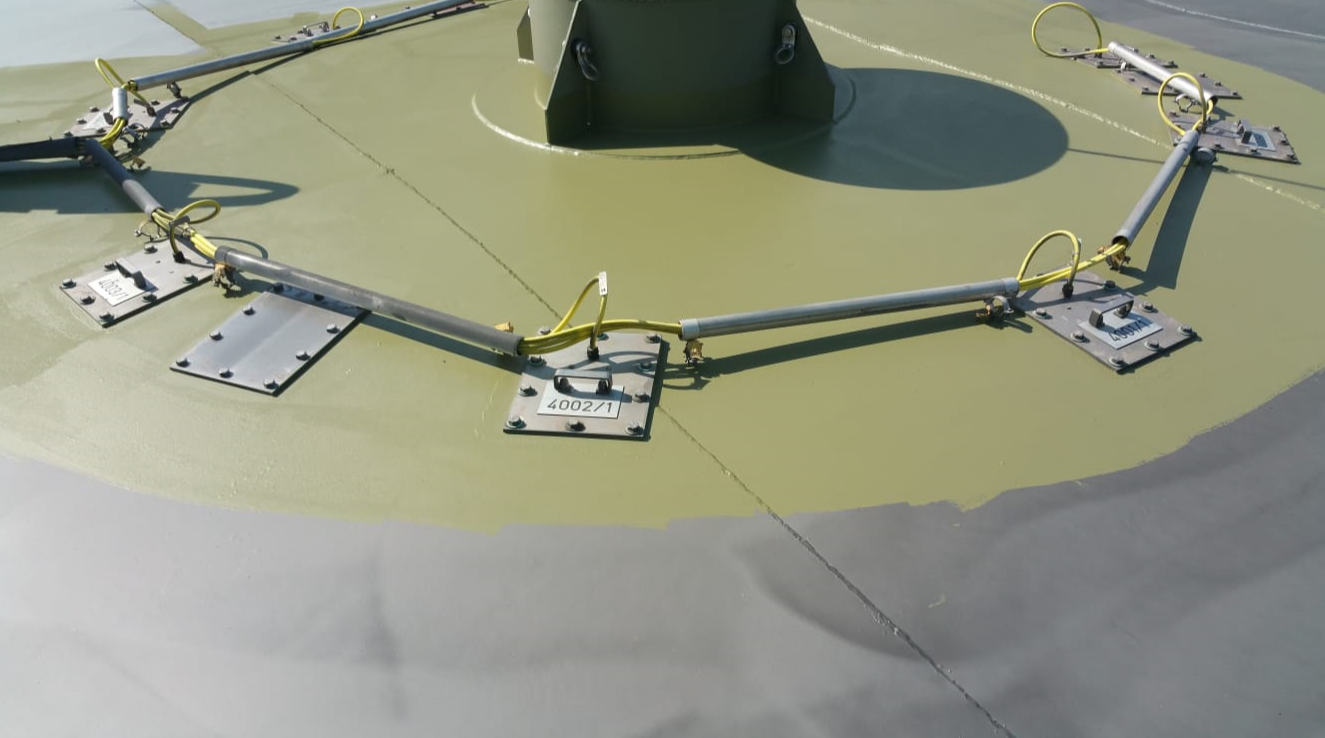

UV and VOC coating protection with

abrasion resistant properties

for floating roof tanks.

coatings for the external

and internal roof protection

of storage tanks in difficult

environments.

with coatings in possible contact

with storage liquids as well as

mechanical sustainable properties.

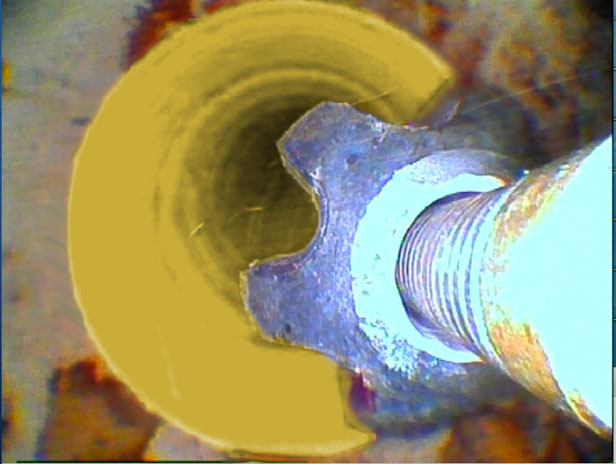

upgrade from single to double

floor with continuous vacuum

monitoring using the

DOPA® technology.

protection with innovative coating

technologies and curing times

under 2 hrs.

and elastic sealing systems for

storage tank ring walls.

resistant coatings for the external

protection of pipes and tubes in

storage farms.

sealings for secondary containments

in concrete or asphalt.

detection systems

(class 1 acc. EN 13160) for

tanks, sumps, wells and pipes.

container for long lasting

integrity using special formulated

sealing solutions.

abrasion resistant and

easy-to-apply sealing coatings.

resistant forecourt and

secondary containment coating with

long-lasting properties

and environmental sustainability.

cleaning technologies and

surface preparation liquids

for heavy rust or sludge removal.

underground storage tanks (UST)

with continuous vacuum monitoring

using the DOPA® technology.

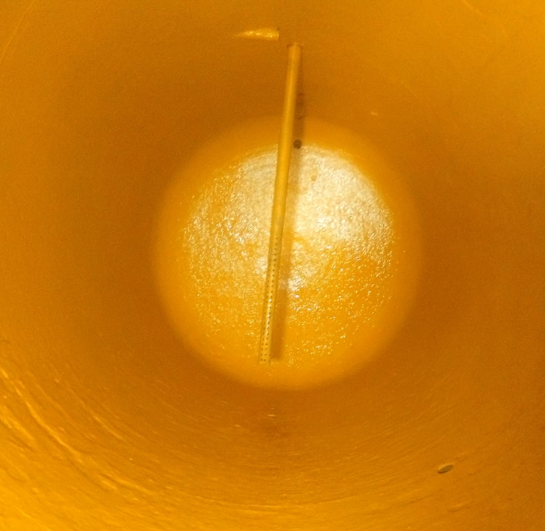

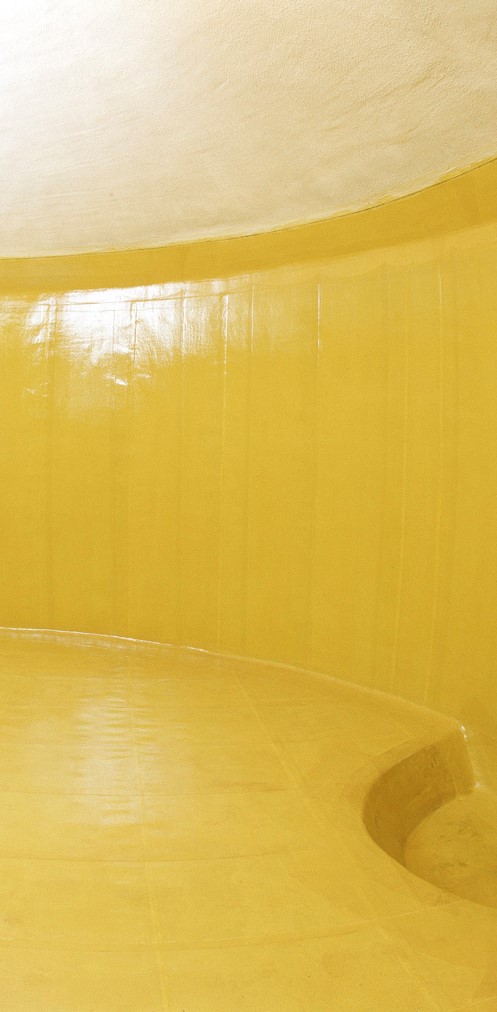

polyester tank rehabilitation

with special bilayer woven

fibreglass providing high

tank integrity.

coatings resistant against

gasoline, diesel, modern biofuels

or even chemicals.

and hole sealing for steel

and FRP tanks without hot-works.

SERVICE STATIONS

Wolftank Austria has solid expertise in the sustainable upgrade of service stations. To avoid soil and water pollution as well as fuel loss, we apply spill prevention solutions in tanks, pipes, sumps and forecourt of retail fuel systems, thus extending these facilities’ lifespan.

In this regard, we have developed our exclusive DOPA® lining system, which transforms single-storage tanks into double-walled tanks. This patented system together with continuous remote monitoring ensures the facility’s protection and integrity while complying with the same quality standards worldwide.

Furthermore, our spill management technologies, degassing and clean-up solutions 100% ensure the safe operation of service stations.

PUBLIC & INDUSTRIAL WATER

Wolftank Austria also protects the handling, preservation and storage of the most valuable liquid of all: water.

Providing drinkable water and containing wastewater is nowadays an increasing challenge for both public and private companies. Our portfolio offers high-quality solutions for the sealing of water sumps, vessels and pipes, irrespective of whether it is fresh, hot, salt or wastewater. Thanks to our innovative coatings systems and our strong retail network, we successfully join the water value chain and preserve the water quality.

With a long-term approach, we offer specially formulated and fully compliant high-performance coating systems in contact with water for the following surface structures:

Long term asset protection against:

- Corrosion

- Deterioration

- Infiltration

- Leaks

Bisphenol A-free | Solvent-free

Compliant to European regulations (Directive no. 98/83/EC of 3 November 1998 (cf. Article 10)).

Drinkable water

In contact with water intended for human consumption, some materials and objects may cause deterioration of the organoleptic, physicochemical or microbiological characteristics of the water. Wolftank Austria ensures the safety of materials and objects used in permanent installations for the supply, treatment and production of water intended for human consumption.

High-temperature water, contaminated water, salt water or wastewater all pose difficult conditions for coating materials and systems. However, our specially formulated coatings and proper application allow satisfactory long-term protection.

Coating Systems for Consumable Water

Specially formulated coating systems according to current health and consumer regulations.

Coating Systems for Industrial Water

Resistant coating solutions for industrial water storage, transport and distribution.

Coating Systems for Wastewater Treatment

High-performance wastewater coatings to sustain a wide range of pollution from contaminated waters.

Coating Systems for Industrial Water

Resistant coating solutions for industrial water storage, transport and distribution.

INDUSTRIAL ENGINEERING

As a result of its commitment to innovation and diversification, Wolftank Austria provides coating solutions to many different sectors. Our product categories are designed and adapted to be applied in the most varied fields, such as industrial coating, tanker truck protection, aircraft fuel tanks, trains, the automotive or even the food industry. In fact, any industrial factory container needs appropriate and adapted cleaning, spill prevention, protection, coating and sealing.

Wolftank Austria’s portfolio successfully responds to all market necessities.

Wolftank Group's industrial coatings in figures

Extract of Bulk Storage References in Refineries and Tank Farms

Final Customer | Lining Systems supplied to Installation Partner | Max. Tank Size |

|---|---|---|

Alma Petroli Italy | DOPA® Double Floor Transformation of Aboveground Storage Tanks and installation of vacuum leak detection system. | D. 18 m |

PetroTank Germany | EPOFLEX® Laminate Floor Lining for Storage Tank | D. 24 m |

Oiltanking Germany | ADALASTIC® Sealing of Ring Wall and Secondary Containment | D. 25 m |

Total Italy | DOPA® Double Floor Transformation for Leak Detection for Aboveground and Underground Storage Tanks and installation of vacuum leak detection system | D. 23 m |

Varo Energy Switzerland | DOPA® Double Floor Transformation of Aboveground Storage Tanks and installation of vacuum detection system | D. 32m |

ENI Italy | DOPA® Double Floor Transformation for Leak Detection for Aboveground and Underground Storage Tanks and installation of vacuum leak detection system. | D. 17 m |

Alpe Adria Pipeline Austria | Tank Roof Lining for Crude Oil Storage Tank | D. 43 m |

Miro Germany | EPOFLEX® Tank Floor Lining and Tank Inside Roof Lining for Storage Tank containing Ethanol | D. 32 m |

Maxcom Petroli Italy | DOPA® Double Floor Lining for various Storage Tanks | D. 28 m |

Cepro Czech Republic | Concrete Tanks Internally Lined with DOPA® on Floor and Shell | D. 44 m |

Extract of Underground Storage Tank References in Gas Stations

Final Customer | Lining Systems Supplied to Installation Partner | No. of Tanks | Project Completion |

|---|---|---|---|

Total Italy | DOPA® Double Wall Conversion and Installation of Vacuum Leak Detection Systems in the Retail Net | > 1000 | 2018 |

EM Italy | DOPA® Double Wall Conversion and Installation of Vacuum Leak Detection Systems in the Retail Net | > 800 | 2017 |

ENI Italy – Austria & France | DOPA® Double Wall Conversion and Installation of Vacuum Leak Detection Systems in the Retail Net | >1500 | 2016 |

Total Africa | ADASYS & EPOFLEX®Structural Tank Lining in different African Countries | > 500 | ongoing |

Total China | DOPA® Double Wall Conversion of Underground Storage Tanks | > 50 | ongoing |

INA Group Croatia | ADAPOX® Structural Tank Reinforcement and DOPA® Double Wall Conversion | > 100 | ongoing |

BP United Kingdom | DOPA® Double Wall Conversion of Underground Storage Tanks | > 300 | 2013 |

Shell China | DOPA® Double Wall Conversion of Underground Storage Tanks | > 50 | ongoing |

Tamoil Italy | DOPA® Double Wall Conversion and Installation of Vacuum Leak Detection Systems in the Retail Net | > 800 | ongoing |

Sinopec China | DOPA® Double Wall Conversion and Installation of Vacuum Leak Detection Systems in the Retail Net | > 1500 | ongoing |