The Fiberglass Tank Sealing System is a rehabilitation of a fiberglass tank in case of any local crack, hole, or similar damage. It is a local patch repair with fiberglass reinforced laminate layer. This sealing system rehabilitates the original tensile strength of the fiberglass tank.

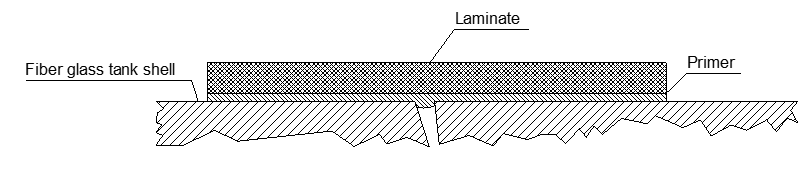

Structure of the Fiberglass Tank Sealing System:

Surface Preparation:

The surface shall be solid, clean, dry, and free of any hydrocarbon residuals. The surface must be lightly sanded with sandpaper.

Sealing:

For each application, a dew point distance of 3°C must be observed.

Primer:

For proper adhesion special primer must be applied directly on the cleaned and solid underground surface. The primer shall be applied with a roller.

Laminate:

The laminate system is a 2 component epoxy based laminate resin and a special woven ultra high strength fiberglass sheet. The laminate can be applied in 1, 2, or even 3 layers up to the damage and the customers’ demand. For laminate, the application uses a roller and previously cut fiberglass sheets.

Tightness Test:

After this patch repair, the tightness of the tank must be tested.

Installation note:

The above information is based on tests by approved institutes (e.g. TÜV Süd Germany) and many years of experience. As the lining performance depends on correct installation, we offer application courses for certified installers and installation supervisors and provide certificates which shall be renewed every 3 years.